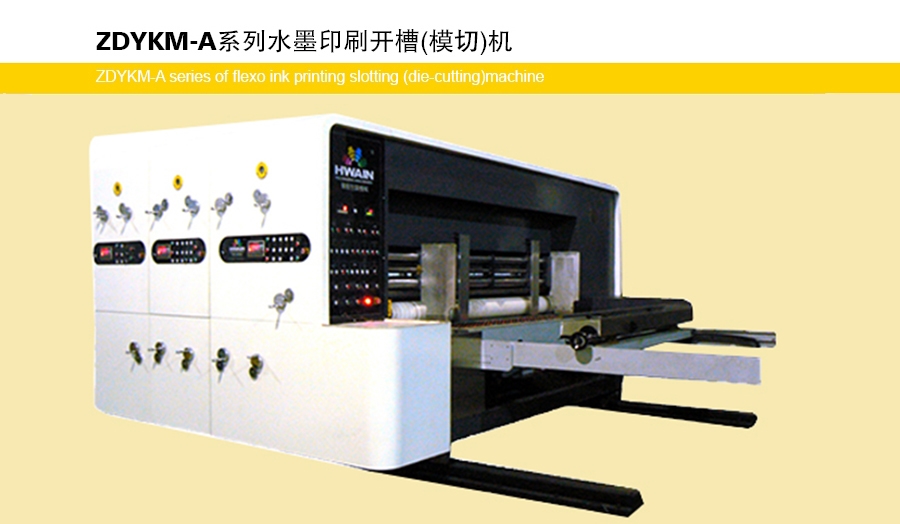

苏州华殷包装机械制造有限公司

苏州华殷包装机械制造有限公司

0512-63658088

产品展示

产品详情

本机简介:

◎ 本机由送纸部、印刷部、开槽部、模切部四部分组成并可根据用户生产情况随意组合。

◎ 本机可以与接料机、边角清除机组成普通全自动生产流水线。

◎ 送纸部采用前缘送纸系统。

◎ 进纸方式可选择无轴进纸或有轴进纸。

◎ 配有高压吸尘、毛刷或毛刷轴二级除尘系统。

◎ 网纹辊可配胶辊或刮刀两种上墨方式,并且可快装组合。

◎ 版辊横移可选择PLC控制或手轮调整。

◎ 传动齿轮采用优质合金钢,渗碳淬火后精磨制造。

◎ 齿轮采用喷淋润滑和润滑脂集中供油润滑系统,并具备油路平衡功能。

◎ 主机、风机采用变频控制,相位电机可采用PLC触摸屏控制或数字控制。

◎ 开槽部采用PLC触摸屏控制可实现纸箱数据输入一键成型,并具有订单储存功能。

Brief Introduction:

◎ This machine is composed of four units, which are feeding unit, printing unit, slotting unit, die cutting unit and it can be freely combined according to user’s production situation.

◎ This machine can make up normal automatic production line with stacker, corner cleaner machine.

◎ Feeding unit adopts lead edge feeder.

◎ The feeding adopts without shaft feeding or shaft feeding.

◎ Equipped with high pressure vacuum device, brush or brush shaft two stage dust removal system.

◎ Anilox roller can be equipped with rubber roller and doctor blade two ways of supplying inking, and be quickly combined.

◎ Printing roller lateral movement is controlled by PLC or handwheel.

◎ Transmission gear adopts high quality alloy steel, fine grinding is manufactured after carburizing and quenching.

◎ Gear adopts spray lubrication and lubricating grease centralized oil supplied lubricating system, and has oil line balance function.

◎ Main and blower adopt frequency conversion control, and the phase motor can be controlled by PLC touch screen or digital control.

◎ The slotting until adopts PLC touch screen to control the data input of the carton, and has the order storage function.

技术参数 Specification:

|

产品系列 |

Product series |

1200系列/1400系列 |

1600系列/1800系列 |

2200系列/2500系列 |

|||||||||

|

|

1420 |

1424 |

1428 |

1432 |

1824 |

1828 |

1832 |

1836 |

2528 |

2532 |

2536 |

2540 |

|

|

机械设计速度(m/min) |

Machanical design speed |

220 |

220 |

220 |

|||||||||

|

最大进纸尺寸(mm) |

Max.feeding size |

1400*2150 |

1400*2550 |

1400*2950 |

1400*3350 |

1800*2550 |

1800*2950 |

1800*3350 |

1800*3750 |

2500*2950 |

2500*3350 |

2500*3750 |

2500*4200 |

|

最小进纸尺寸(mm) |

Min.feeding size |

320*650 |

430*750 |

540*950 |

|||||||||

|

最大印刷面积(mm) |

Max.printing size |

1400*2000 |

1400*2400 |

1400*2800 |

1400*3200 |

1800*2400 |

1800*2800 |

1800*3200 |

1800*3600 |

2500*2800 |

2500*3200 |

2500*3600 |

2500*4000 |

|

标准印版厚度(mm) |

Standard printing plate thickness |

7.2 |

7.2 |

7.2 |

|||||||||

|

套色精度(mm) |

Color accuracy |

≤0.5 |

≤0.75 |

≤1.0 |

|||||||||

|

金属上墨辊(目数) |

Metal ink roll(mesh number) |

250-280 |

250-280 |

250-280 |

|||||||||

|

陶瓷上墨辊目数(选配) |

Ceramic ink roller on the mesh(optional) |

300-450 |

/ |

/ |

|||||||||

|

上墨方式 |

Ink on the way |

橡胶轴 |

橡胶轴 |

橡胶轴 |

|||||||||

|

送纸方式 |

Type of paper-feeding |

前缘+滚轮送纸 |

前缘+滚轮送纸 |

前缘+滚轮送纸 |

|||||||||

|

印刷滚筒横移(mm) |

Printing roller sway |

±6 |

±6 |

±6 |

|||||||||

|

最大模切尺寸 |

Max.die cutter size |

1400*1950 |

1400*2350 |

1400*2750 |

1400*3150 |

1800*2350 |

1800*2750 |

1800*3150 |

1800*3550 |

2500*2350 |

2500*2750 |

2500*3150 |

2500*3550 |

|

最小开槽间距(mm) Min. slotting distance |

正刀 Positive cut |

185*185*185*185 |

/ |

/ |

|||||||||

|

反刀 Reverse cut |

270*60*270*60 |

290*60*290*60 |

315*60*315*60 |

||||||||||

|

最大槽深(mm) |

Max.slotting depth |

350 |

450 |

625 |

|||||||||

| 上一页 | 首页 | 下一页 |